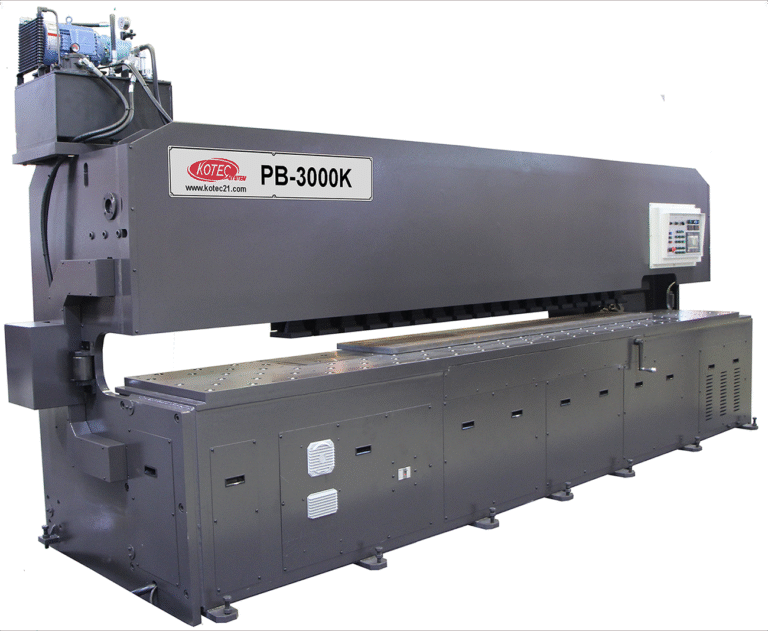

Plate Double-Sided Bevelling Machine PB-3000K

A high-precision, high-speed bevelling machine designed for finishing plate edges on both sides simultaneously. This efficient solution is ideal for preparing plates before welding in structural and heavy fabrication environments.

Key Features

- Dual-Side Bevelling: Simultaneous upper and lower cutting heads improve throughput and consistency.

- Digital Angle Control: Bevel angles (θ₁ and θ₂) are precisely adjustable via digital interface for repeatable, accurate setup.

- Replaceable Carbide Inserts: Tungsten carbide cutting edges ensure long tool life and easy maintenance.

- Robust Hydraulic Clamping: Secure plate fixation and simplified operation thanks to a hydraulic clamp system.

Applications

This machine is built to deliver reliable bevelling for heavy plate preparation across industries, including:

- Structural steel fabrication

- Bridge and infrastructure engineering

- Shipbuilding and offshore platforms

- Manufacturing of heavy machinery components

Why Choose the Plate Bevelling?

The PB-3000K focuses on speed, accuracy, and operator convenience—making it an excellent solution for facilities needing clean, consistent bevel preparation. With digital beveling control and replaceable carbide inserts, it lowers downtime and ensures precision across high-volume production runs.

For more information, visit the official product page:

Technical Specifications

| Specification | Details |

|---|---|

| Model | PB-3000K |

| Max Plate Length | 3,000 mm |

| θ₁ Range | 0° – 70° |

| θ₂ Range | 0° – 60° |

| Max Plate Thickness (T) | 60 mm |

| Max Bevel Depth C₁/C₂ @ 45° | 18 mm |

| Cutting Speed | 100 – 750 mm/min |

| Clamp Sets | 18 sets |

| Cutting Heads | 2 units (upper & lower) |

| Dimensions (L×W×H) | 4 850×1 710×1 950 mm |

| Weight | 8,500 kg |